With a focus on the activities of Khanjani Polymer Industries as the largest and first geomembrane manufacturer in Iran, this article examines “Modern Techniques in the Design and Implementation of Waterproofing and Drainage Systems Using Geosynthetics.” First, we will review the fundamental concepts, then introduce emerging methods and techniques, and finally discuss challenges, solutions, and implementation requirements.

The goal is to provide a comprehensive overview of the application of geosynthetics in waterproofing and drainage and clarify the role of Khanjani Company in this field.

Advanced Drainage with Geomembrane and Geotextile

In civil and environmental projects such as landfills, wetlands, canals, tunnels, and underground structures, waterproofing and excess-water drainage are essential elements of the system. The use of geosynthetic materials—such as geomembranes, geotextiles, geodrains, geocells, and geocomposites—has become a widely accepted modern solution worldwide and in Iran over recent decades.

Khanjani Polymer Industries, as a manufacturer of geomembranes and geosynthetic materials, has been a driving force behind these developments in Iran. Therefore, examining modern techniques with an emphasis on the capabilities of this company is of great importance.

Geosynthetics in Waterproofing and Drainage

- Polymeric sheets with very low permeability installed on the base or walls of structures to create an impermeable barrier.

- Geotextiles are layers or fabrics made of synthetic fibers used as separators, filters, or protective layers.

- Geodrains are three-dimensional drainage layers with a drainage core, providing both drainage and protection.

- Geocomposites combine multiple geosynthetics (e.g., geotextile + geonet) for specific applications.

Waterproofing and Drainage Functions

Waterproofing refers to creating a barrier preventing water or liquid penetration into the structure. Drainage refers to directing and discharging excess water into a controlled path. The combination of these two—especially in underground structures or areas with high moisture or groundwater—is essential.

Modern Techniques in Design and Construction

Below are several modern techniques that have become common over the last decade:

Multi-layer Systems with Defined Functions

A multi-layer system is created where each layer performs a specific function—for example, a geomembrane layer for waterproofing, a geotextile underneath for protection, and a geodrain layer for drainage. This approach both controls seepage and accelerates water discharge.

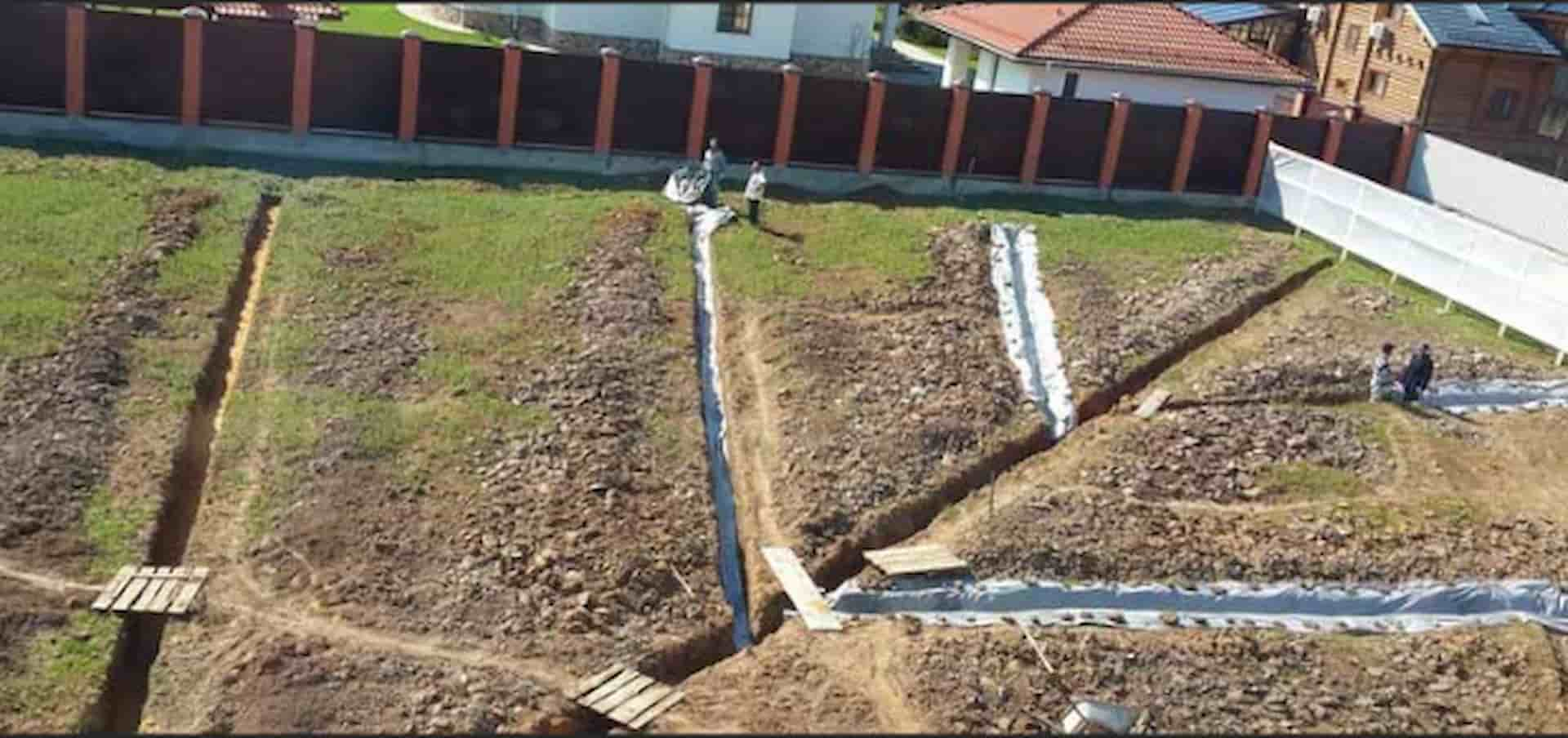

Example: In deep excavation projects, the surface is first prepared, then the geomembrane is installed and welded point-by-point; a geotextile layer is placed on top for puncture protection; and walls are fitted with geodrain layers.

Welding Technology and Quality Control

For geomembranes, the quality of seam welding and overlaps is crucial. Modern techniques combine automatic welding equipment (such as wedge welders) with post-installation leak detection tests (such as electrical liner integrity surveys).

Khanjani can provide appropriate installation equipment and processes as a manufacturer.

Selecting Materials Based on Environmental Conditions

Geosynthetic materials must match the climatic conditions, hydrostatic pressure, soil type, water flow rate, and groundwater level. For example, geomembrane thickness must correspond to water pressure.

Khanjani manufactures geomembranes in various thicknesses to meet such needs.

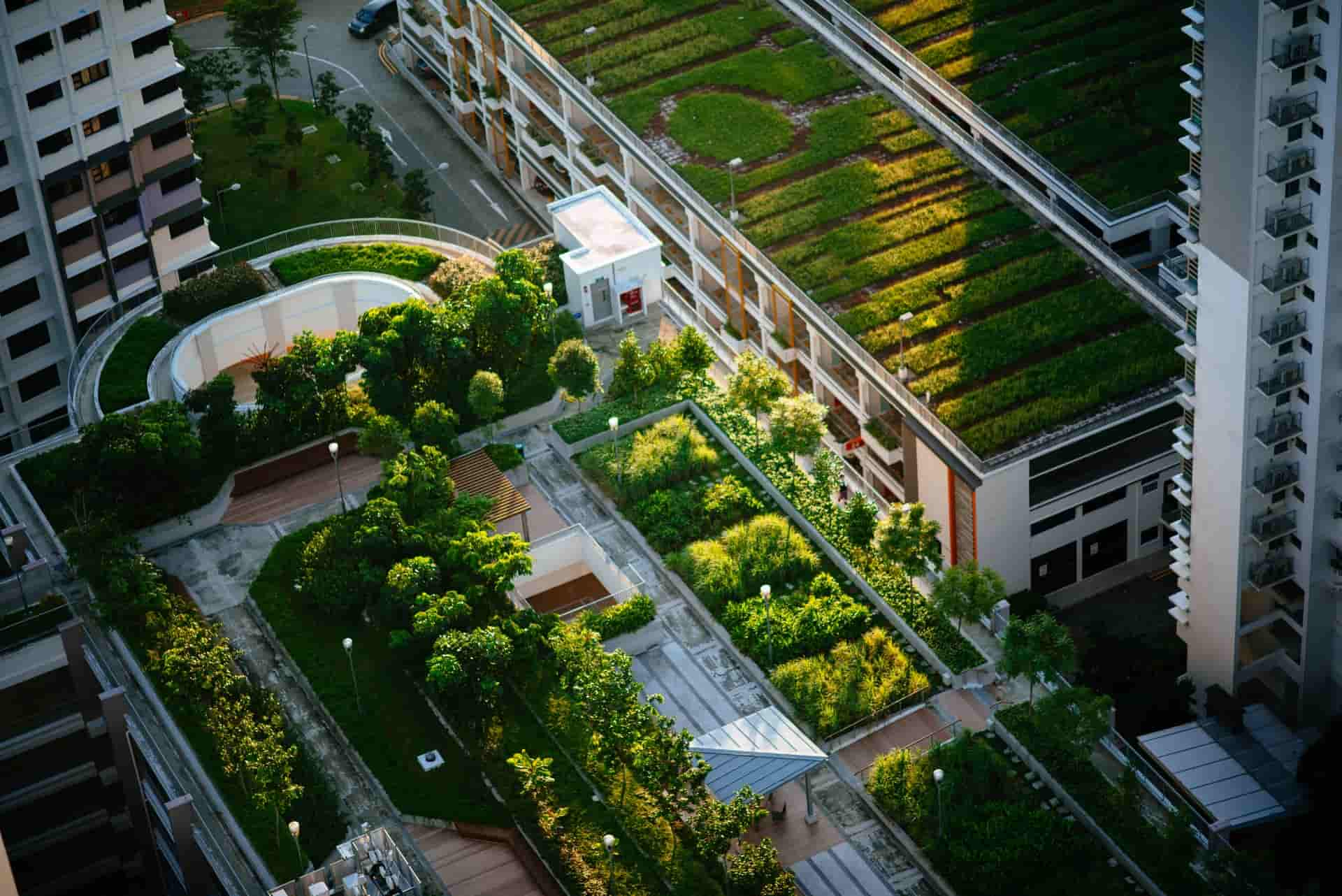

Use of Geocells and Geocomposites for Slopes and Difficult Areas

On slopes, retaining walls, or rooftops, geocells are an advanced technique. Their honeycomb structure enhances soil stability.

In walls and tunnels, geocomposites can serve as both a drainage layer and geomembrane protection.

Post-Installation Monitoring Systems

Ensuring long-term system performance is a key challenge. Techniques such as electrical liner integrity surveys help identify leaks after installation.

Manufacturers and contractors—including Khanjani—can ensure quality by offering after-sales services and periodic monitoring.

Design Requirements and Influencing Factors

This section outlines the key parameters and requirements for proper design and implementation:

1. Understanding Project Conditions

Type of structure (landfill, reservoir, canal, underground building) Hydrostatic pressure / groundwater conditions Soil type, permeability, erosion activity, or settlement Climate conditions (UV exposure, temperature, rainfall) All these factors influence material selection and installation methods.

2. Surface Preparation

The surface must be free of sharp objects, mud, and major unevenness. Many references emphasize surface preparation before installing geomembranes.

A protective layer (geotextile or similar) before geomembrane installation is essential.

3. Protective Layer and Drainage Layer

To prevent physical damage to geomembranes, the use of geotextile or geodrain is recommended. Geodrains, which include a drainage core, provide separation, protection, and water discharge.

4. Overlap and Welding

The overlap width, welding method, installation speed, and temperature conditions must be carefully controlled. After installation, leak testing must be carried out.

5. Monitoring, Maintenance, and Operation

A safe system is one designed for long-term service life (e.g., 60 years) and includes regular maintenance.

Khanjani provides technical guidance and after-sales support to assist clients.

The Role of Khanjani Polymer Industries

As a domestic producer of geomembranes and geosynthetics, Khanjani has several strategic advantages:

- Domestic manufacturing: reducing import dependency and shortening supply times.

- Localized technical knowledge: enabling material adaptation to Iran’s soil and climate conditions.

- Technical and installation services: supporting projects from product selection to installation and monitoring (as stated on their website).

Thus, when a project intends to utilize modern geosynthetic techniques, cooperation with Khanjani is advantageous.

Challenges and Solutions

Although modern techniques are highly effective, some challenges remain:

Challenges of Advanced Drainage Using Geomembrane and Geotextile

- Installation quality: Poor installation may reduce system performance.

- Iran’s soil and groundwater conditions: Some areas have high groundwater or highly permeable soils, requiring more precise design.

- Initial cost: Although cost-effective long-term, modern systems may have higher initial costs than traditional methods.

- Monitoring and maintenance: Without planned maintenance, the system may deteriorate prematurely.

Solutions

- Selecting skilled contractors experienced in geosynthetic installation

- Using technical consultation services from the manufacturer (e.g., Khanjani)

- Planning for long-term monitoring, inspections, and preventive maintenance

- Selecting proper material combinations suited to project conditions

- Performing full documentation, post-installation testing, and quality verification

Summary of Modern Techniques in Waterproofing and Drainage Design and Construction

In conclusion, modern design and construction techniques for waterproofing and drainage systems using geosynthetics—particularly geomembranes and geodrains, geotextiles, and geocomposites—provide significant opportunities for improving the performance and lifespan of civil, environmental, and underground structures in Iran. Khanjani Polymer Industries, as a leading manufacturer, plays a key role in implementing these techniques.

With proper design, installation, monitoring, and maintenance, structures can achieve longer service life, better performance, and reduced maintenance costs.

It is recommended that future projects in Iran—especially those facing water or seepage challenges—utilize geosynthetic systems and the technical services of reputable companies such as Khanjani to prevent leakage, settlement, or long-term costs associated with traditional methods.