Geocell Insights

An Overview of Modern Soil Stabilization Technology by Khandjani Polymer Industries – The First and Largest Geocell Manufacturer in Iran

In recent decades, the rapid growth of construction, road-building, oil and gas, and urban development projects in Iran has highlighted the need for innovative methods of soil stabilization, erosion control, and infrastructure durability. One of the most advanced achievements in this field is the Geocell — an intelligent geosynthetic system whose three-dimensional cellular structure has revolutionized soil engineering and deformation control.

In Iran, Khandjani Polymer Industries, as the first and largest manufacturer of geocells, has combined industrial-scale production capacity with localized technical expertise. This achievement has improved the quality of domestic polymer products, provided a reliable alternative to imports, and opened a new chapter in civil and environmental engineering.

What Is a Geocell and How Does It Work?

A geocell is essentially a three-dimensional network of interconnected polymer strips that, when expanded and filled with materials such as soil, gravel, or concrete, forms a strong cellular structure. Due to the lateral confinement provided by the cell walls, the load-bearing capacity of the soil is increased, and lateral deformation is minimized.

The performance of a geocell can be summarized in three words:

Confinement – Load Distribution – Subgrade Reinforcement.

In practice, the geocell acts like a flexible yet strong cage that confines soil particles, preventing displacement and slippage. This makes it ideal for road subgrades, slopes, embankments, shorelines, pipelines, and soft foundations.

Raw Materials and Production Process at Khandjani Polymer Industries

Khandjani Polymer Industries uses high-density polyethylene (HDPE) as the main raw material to produce geocells with high tensile strength, thermal and chemical stability, and a lifespan exceeding 50 years. The polymer strips are formed using dedicated extrusion lines with precise control over temperature, pressure, and thickness.

The strips are then connected at standard intervals using ultrasonic or thermal welding techniques, forming cells of various dimensions and heights. This unique industrial process, developed through years of research and experience, adheres to international ASTM and ISO standards.

By localizing production equipment and molds, the company has successfully achieved product quality equivalent to global brands — at a competitive cost.

Types and Applications of Geocells

Geocell products are categorized based on strip thickness, cell height, and intended application. At Khandjani Polymer Industries, the following types are produced and supplied:

- Roadway Geocells: For stabilizing soft subgrades in roads, railways, ramps, and industrial yards.

- Erosion Control Geocells: Used on slopes, channels, and embankments to prevent sliding and soil washout.

- Structural Geocells: Filled with concrete for constructing load-bearing pavements and platforms.

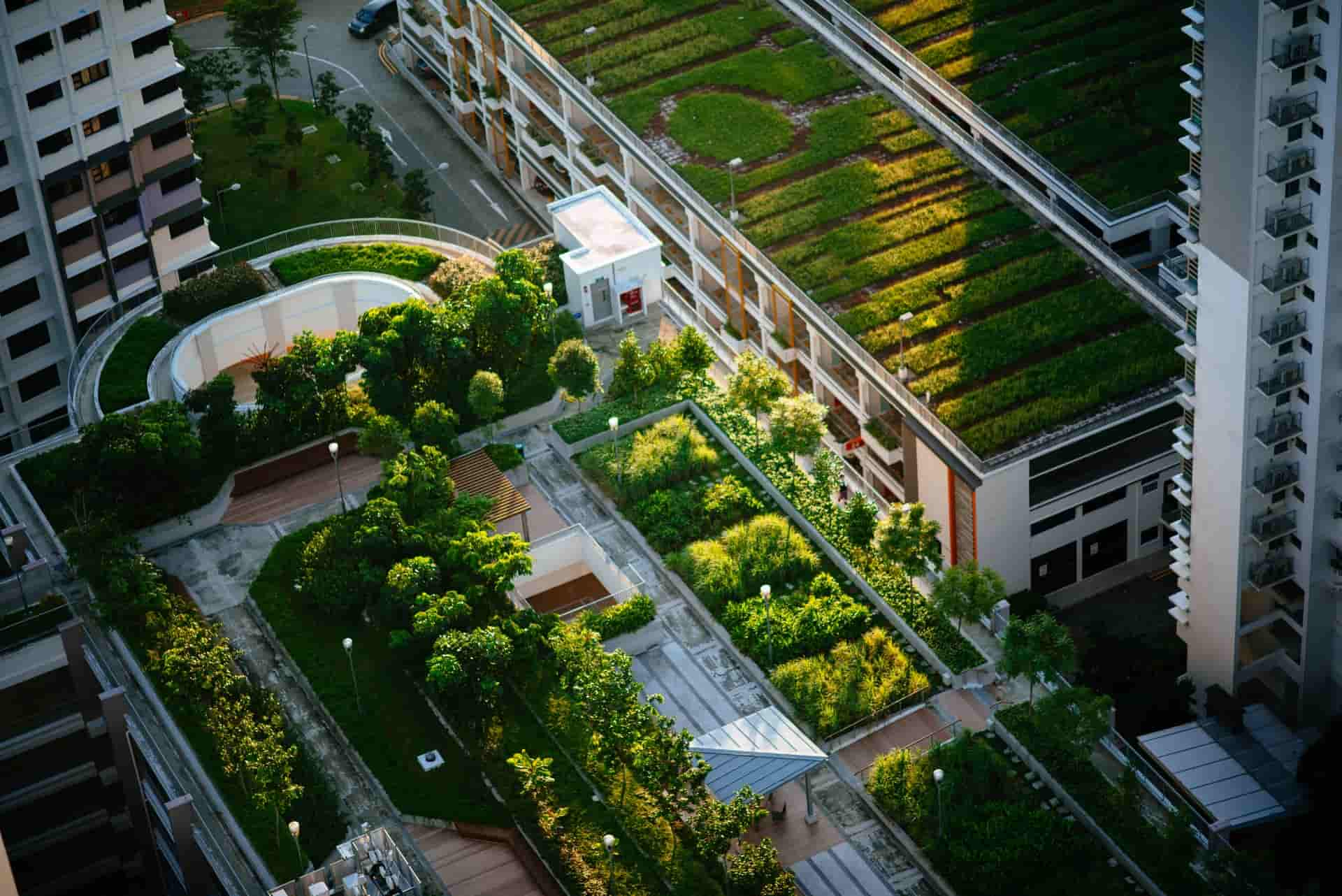

- Green or Eco Geocells: Designed for landscaping and urban green spaces, allowing vegetation growth within the cells.

By selecting the right geocell type, project owners can reduce material consumption by up to 50% and execution costs by up to 30%, while significantly improving geotechnical performance.

Advantages of Using Geocells in Civil Projects

Using geocells in civil engineering applications offers numerous technical, economic, and environmental benefits:

- Enhanced load-bearing capacity of weak soils

- Reduced thickness of base and subbase layers

- Uniform load distribution and reduced localized settlement

- Prevention of slope erosion and surface sliding

- Utilization of locally available, low-cost materials

- Fast installation and easy transportation

- High durability against UV radiation, chemicals, and temperature variations

Thanks to these advantages, geocells are now widely used in major national projects, including southern oil and gas fields, northern mountain roads, southern coastal structures, and municipal infrastructure developments.

The Role of Khandjani Polymer Industries in Localizing Geocell Technology

During the years when most geosynthetic products were imported, dependence on foreign suppliers and currency challenges posed serious obstacles for engineers and contractors. Khandjani Polymer Industries invested in geocell production technology and knowledge transfer to turn this challenge into an opportunity.

Today, the company not only fully meets domestic demand but has also taken steps toward exporting to regional markets. Strict quality control, advanced laboratory facilities, and collaborations with universities and research centers are among the company’s key strengths.

Production is carried out in compliance with ASTM D638, ASTM D5035, ASTM D5321, and ISO 9001 standards, with each batch accompanied by a dedicated quality certificate.

Quality Control Tests and Performance Assurance

To ensure durability and performance, the following tests are performed at Khandjani Polymer Industries’ laboratory:

- Tensile strength testing of geocell strips

- Weld joint strength testing

- Thermal and UV aging tests

- Chemical and environmental resistance tests

- Precise dimensional verification of cells

These quality checks guarantee consistent performance of geocells under diverse climatic conditions — from the humid north to the hot and arid southern regions of Iran.

Synergy Between Geocells and Other Geosynthetic Products

One major advantage of working with Khandjani Polymer Industries is the ability to obtain complete geosynthetic systems from a single, trusted source. In addition to geocells, the company supplies complementary products such as geomembranes, geotextiles, and geodrains.

Combining these products results in high-performance systems for:

- Sealing and drainage in landfills and evaporation ponds

- Reinforcement of steep slopes using geocells and geotextiles

- Road subgrade stabilization using both geocells and geomembranes to prevent water infiltration

This integrated approach not only reduces project costs but also ensures better design compatibility and longer service life.

The Future of Geocell Technology in Iran

The global trend toward sustainability and green development highlights the growing role of eco-friendly materials such as geocells. By allowing the use of local materials, minimizing aggregate extraction, and increasing structural longevity, geocells contribute significantly to reducing the environmental impact of civil projects.

With a forward-thinking approach, Khandjani Polymer Industries is developing a new generation of geocells with enhanced weld strength, lighter weight, and recyclability. The company’s vision is to position Iran among the leading regional producers of geosynthetics, offering products tailored to local engineering needs.

Summary: Key Facts About Geocells

Geocells are innovative polymer-based systems that have redefined the boundaries of geotechnical engineering. With their three-dimensional structure, they transform weak subgrades into strong, durable, and cost-efficient foundations.

In Iran, Khandjani Polymer Industries, supported by localized expertise, modern equipment, and skilled professionals, stands as the first and largest geocell manufacturer in the country, delivering world-class quality products that promote sustainable national infrastructure.

The company’s vision is an independent Iran in geosynthetic technology and the export of domestic knowledge and products — a path built upon innovation, experience, and trust in local capabilities.

Khandjani Polymer Industries is also a regional manufacturer of geomembrane welding machines. For orders and technical support, feel free to contact us.

📞 Khandjani Polymer Industries

- The first and largest geocell manufacturer in Iran

- Phone: +98 21 88009861 and +98 21 88009862

- Website: shahriyarbaspar.com

- Email: info@khanjanipolymer.com