Types of Geosynthetics and Their Applications in Engineering Projects

In recent decades, the rapid advancement of polymer materials technology has led to remarkable progress in civil engineering, environmental protection, and water resources management. One of the most significant outcomes of this progress is the development and use of geosynthetics—synthetic materials that interact with soil, rock, and other geologic media to provide mechanical, hydraulic, or separation functions.

Today, geosynthetics play a key role in various projects such as road construction, dam building, landfill lining, drainage systems, erosion control, and pond lining.

This group of products includes several main types: geotextiles, geomembranes, geocells, and geodrains, each known for its specific properties and applications.

1. Geotextiles

Geotextiles are synthetic fabrics made of polypropylene or polyester fibers, produced using either woven or non-woven techniques.

Thanks to their high tensile strength, good permeability, and resistance to chemical and biological degradation, geotextiles are widely used in civil and environmental engineering projects.

Main Applications of Geotextiles:

- Separation: Preventing the mixing of different soil layers, for example, between subbase and base layers in road construction.

- Filtration: Allowing water to pass while retaining soil particles, such as in retaining wall drainage or subsurface drainage systems.

- Reinforcement: Enhancing the stability of weak or soft soils in embankments, ramps, and slopes.

- Protection: Protecting geomembrane liners from mechanical damage during installation.

In pond lining projects using geomembranes, nonwoven geotextiles are commonly used as protective layers above and below the geomembrane to prevent puncture or tearing caused by contact with sharp stones.

2. Geomembranes

Geomembranes are impermeable polymer sheets used to prevent the leakage of liquids or gases. The most common types are made of high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE).

Key Features of Geomembranes:

- Excellent resistance to water and gas permeability

- Outstanding durability against UV radiation, chemicals, and microorganisms

- High flexibility and adaptability to different temperatures

- Service life exceeding 30 years under proper conditions

Main Applications of Geomembranes:

- Lining of agricultural and aquaculture ponds

- Landfill liners and covers

- Sealing of earth dams and water conveyance canals

- Lining of water, wastewater, and industrial reservoirs

In Iran, Khanjani Polymer Industries is recognized as the first and largest manufacturer of geomembrane sheets.

Using advanced extrusion lines, the company produces HDPE, LLDPE, and PVC geomembranes in various thicknesses and widths.

Khanjani Polymer not only supplies high-quality geomembrane sheets but also designs and manufactures geomembrane welding machines, including Hot Wedge and Extrusion Welding models for precise, leak-proof on-site installation.

With these technologies, geomembrane pond lining is executed faster, more accurately, and more economically than traditional methods (such as concrete or mortar). These liners ensure complete water-tightness, long service life, and minimal maintenance requirements.

3. Geocells

A Geocell is a three-dimensional honeycomb structure made of polyethylene. When expanded and filled with soil, gravel, or concrete, it significantly increases shear strength and subgrade stability.

Advantages and Features of Geocells:

- Uniform load distribution and reduced settlement

- Erosion control on slopes and soil surfaces

- Improved stability of retaining walls and embankments

- High resistance to dynamic loads and vibrations

Applications:

- Subgrade stabilization for roads and access routes

- Erosion control in slopes and drainage channels

- Construction of lightweight and flexible retaining walls

- Stabilization of soil slopes in civil projects

In projects such as slope stabilization or landfill construction, geocells are often combined with geotextiles and geomembranes to provide integrated functions of drainage, reinforcement, and impermeability.

4. Geodrains

Geodrains (or geodrainage systems) are synthetic drainage structures composed of polymeric layers with a drainage core that enables the quick transfer of subsurface water.

Main Components of Geodrains:

Core: Usually made of polyethylene or polypropylene with a grid or corrugated structure to create flow channels.

Geotextile cover: Prevents soil particles from entering the core and clogging the system.

Applications:

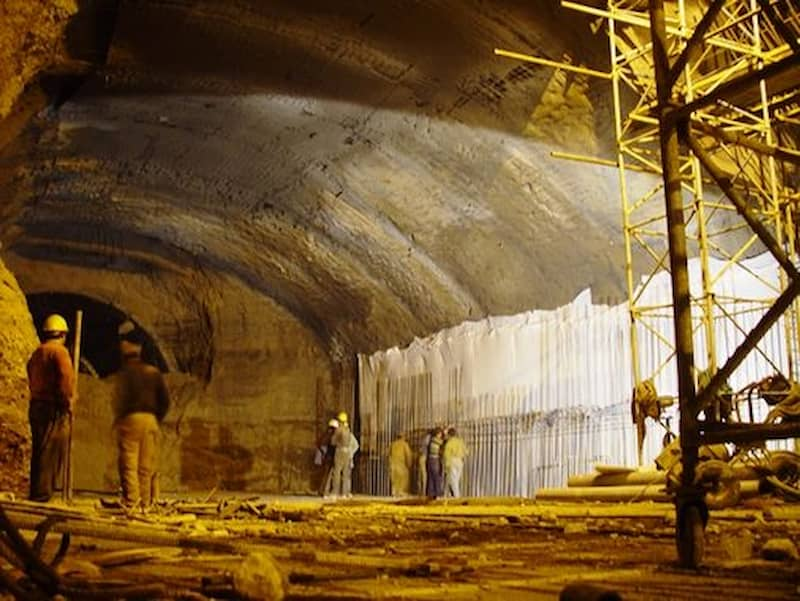

- Drainage behind retaining walls and tunnels

- Leachate drainage systems beneath geomembranes in landfills

- Agricultural and sports field drainage

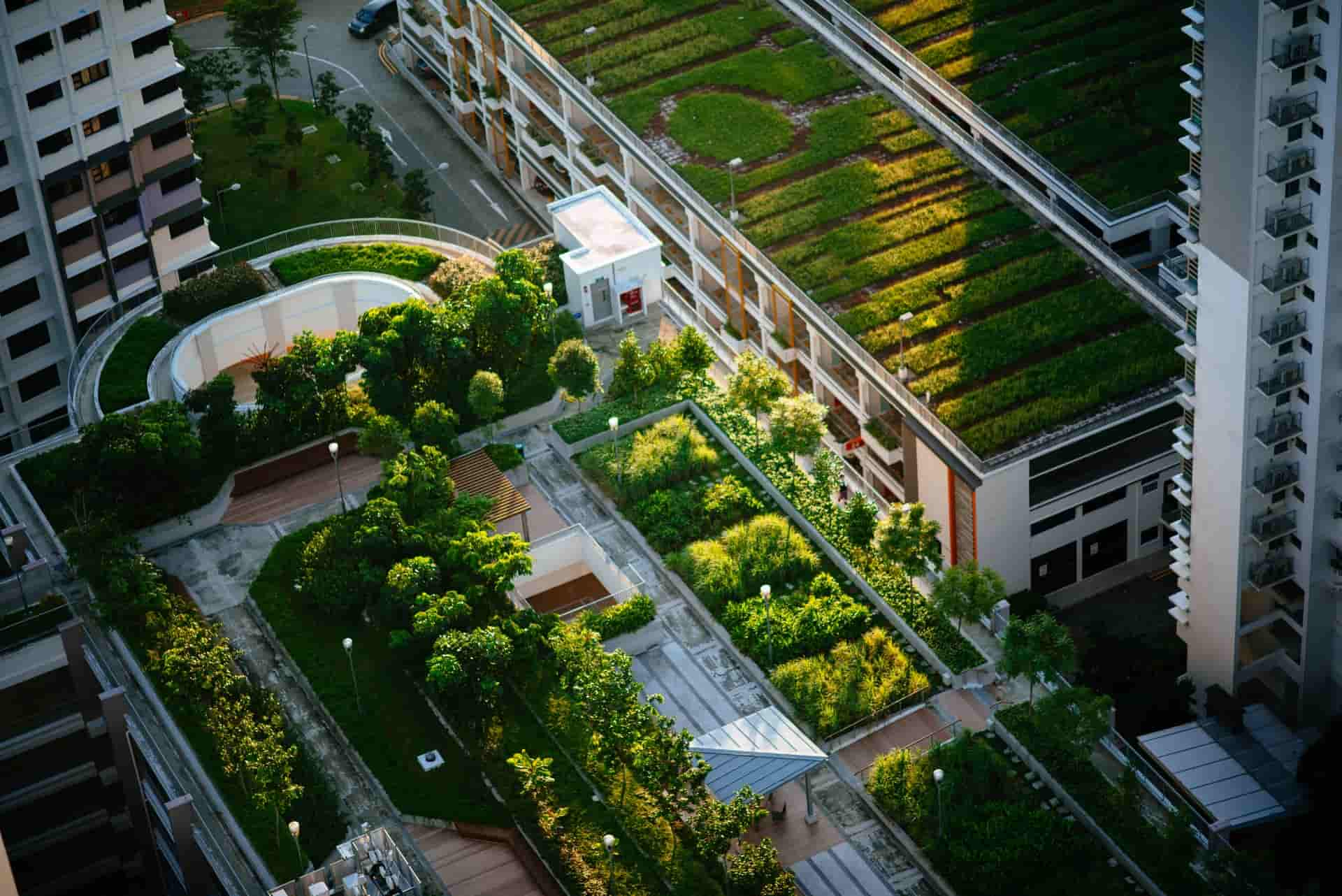

- Water collection and discharge beneath ponds and green roofs

Using geodrains in combination with geomembranes and geotextiles increases the lifespan of lining systems and reduces hydrostatic pressure.

Integration of Geosynthetics in Engineering Projects

In many civil and environmental projects, multiple geosynthetic materials are used together to achieve optimal system performance.

For example:

– In landfills, geomembrane liners (for sealing), geotextiles (for protection and filtration), and geodrains (for leachate drainage) are layered sequentially.

– In agricultural ponds, the soil surface is first leveled, then nonwoven geotextile is placed as a sublayer. Next, a geomembrane liner produced by Khanjani Polymer Industries is installed using professional welding machines for full waterproofing.

– On soil slopes or retaining walls, geocells are used for stability and erosion control, often combined with geotextiles and geodrains.

Advantages of Using Geosynthetics

- Reduced construction costs and time compared to traditional methods

- Extended service life due to environmental resistance

- Reduced use of natural materials such as sand and gravel

- Enhanced environmental performance by preventing soil and water contamination

- Quick installation, lightweight, and recyclability

The Role of Khanjani Polymer Industries in the Development of Geosynthetics in Iran

With over two decades of experience in polymer product manufacturing, Khanjani Polymer Industries is a pioneer in developing geosynthetic technologies in Iran.

By operating advanced production lines, the company manufactures geomembrane sheets with thicknesses ranging from 0.5 to 3 mm and widths up to 7 meters, used in major national projects such as dams, agricultural ponds, wastewater treatment plants, and municipal landfills.

In addition to production, Khanjani Polymer actively contributes to the supply of installation equipment and the training of technical personnel.

Its production of geomembrane welding machines meeting international standards has made the company a key reference for professional geomembrane installation across Iran.

Summary: Introduction to Geosynthetics – Applications, Advantages, and Challenges

Geosynthetics represent a new generation of engineering materials that have revolutionized the design and construction of civil and environmental projects.

From durable, filterable geotextiles to impermeable geomembrane liners, from three-dimensional geocell structures to efficient geodrain systems, all contribute to greater durability, reduced costs, and enhanced environmental protection.

Among them, Khanjani Polymer Industries—as the leading geomembrane manufacturer in Iran—has played a major role in localizing geosynthetic technologies, improving execution quality, and promoting sustainable infrastructure development in the country