Comprehensive Quick Guide to Geocell Installation

In road construction, slope stabilization, and erosion control projects, proper installation of Geocell — a three-dimensional cellular confinement system — is essential. In this practical and concise guide, we explain step-by-step how to install Geocell, focusing on the sheets manufactured by Shahriyar Baspar Aryan Group — the largest Geocell sheet producer in Iran and the Middle East — to enhance installation speed and quality.

- Understanding Geocell and Its Applications

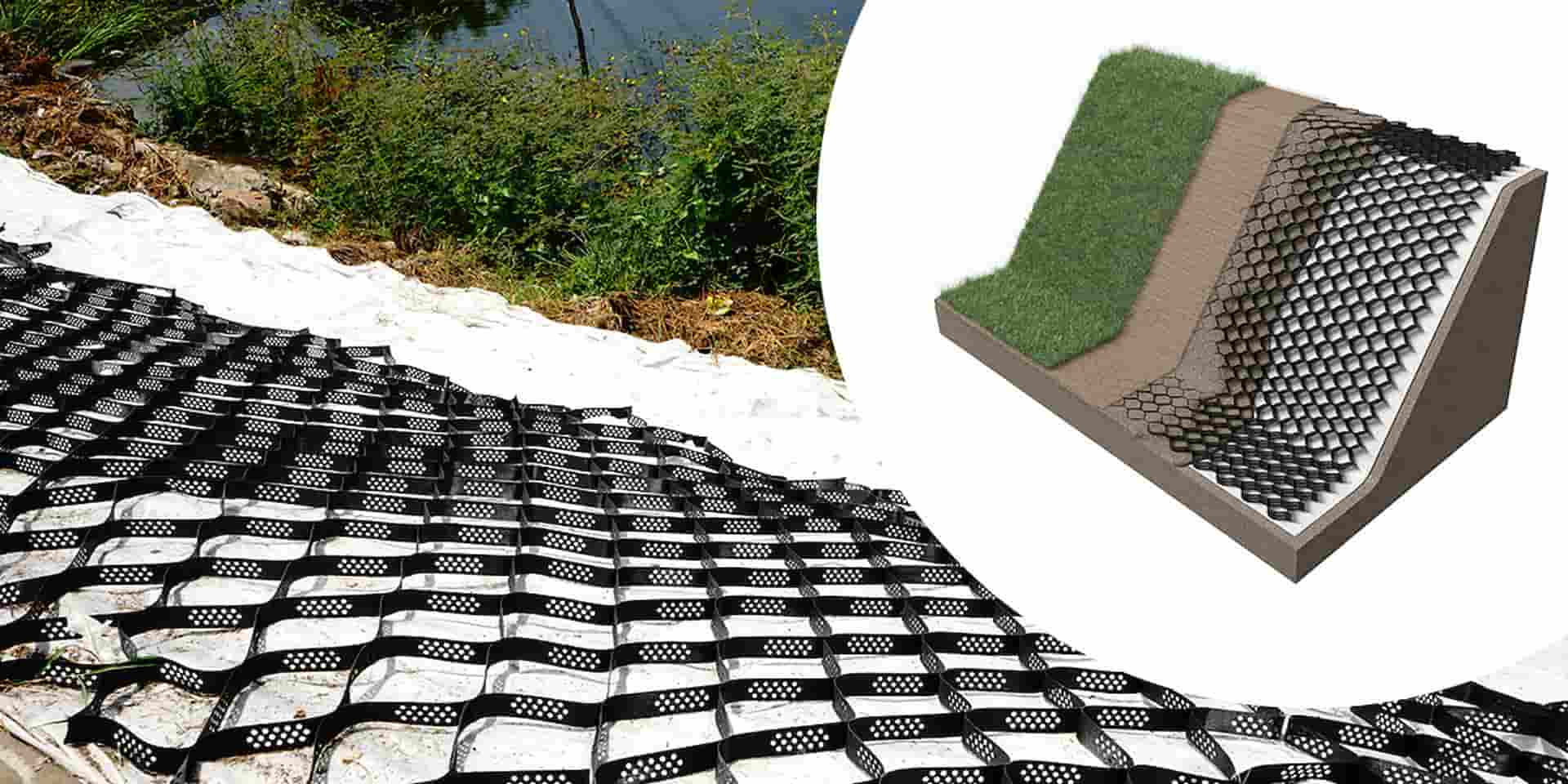

Geocell: A three-dimensional polyethylene network that creates a stable structure for the infill material (gravel, soil, or lightweight concrete) by interconnecting cells.

Applications: slope stabilization, road base reinforcement, erosion control, retaining structures, and temporary load-bearing surfaces.

Advantages: load distribution, reduced settlement, improved shear strength, and lower surface material costs.

Geocell Features and Benefits

- Before starting the installation process, it’s important to highlight key features and advantages of Geocell to understand why it’s so widely used:

- Geocells are made of polyethylene (usually high-density polyethylene – HDPE) and have excellent chemical and biological resistance.

- The cellular structure confines the infill material (such as gravel or crushed stone) and prevents lateral movement.

- Lightweight, easy to transport, flexible in expansion and contraction, and adaptable to uneven ground surfaces.

- Using Geocell reduces infill costs, shortens construction time, and improves the durability and stability of the structure.

- Geocells are used in base reinforcement, slope protection, retaining walls, access roads, subbase layers, erosion control, and more.

With Geocells manufactured by Shahriyar Baspar Aryan, available in various dimensions, projects from small to large scales can be efficiently executed.

- Site Preparation

1. Site Clearing: Remove all debris, roots, organic materials, and large stones to achieve a smooth and even surface.

2. Excavation or Leveling: Depending on the design, excavation to the required depth may be necessary for proper Geocell placement.

3. Initial Compaction: Compact the base layer using suitable equipment (vibratory or static roller) until the desired compaction ratio (e.g., 95% standard) is achieved.

4. If necessary, install a separation layer: When required, a geotextile or filter layer should be placed beneath the Geocell to separate and drain the subgrade, preventing mixing of the soil with the infill.

- Unfolding and Fixing the Geocell Panels

1. Panel Delivery: Geocell panels are delivered in a compact form; handle them carefully to prevent damage.

2. Unfolding the Panels: Gently expand the panels until the honeycomb structure is fully opened.

3. Initial Positioning: Lay the panels in the correct orientation (in the slope direction or as per the project design).

4. Securing the Edges: Use steel pins, U-shaped anchors, or fixing tools at the edges and corners to hold the panels in position.

5. Connecting Panels: When multiple panels are required, connect them using clips, fasteners, or standard welding techniques.

- Filling the Cells

Choose appropriate infill material: for load-bearing surfaces, use crushed gravel or cobbles; for erosion control, use mixed soil with aggregates or lightweight concrete.

Fill the cells in layers and compact them lightly to ensure uniform distribution and to prevent post-construction settlement.

- Panel Connection and Overlap

At panel joints, provide overlap according to specifications (typically 10–30 cm) and secure the edges using clips or stitching to maintain structural integrity.

- Safety and Quality Control Tips

To ensure fast and standard Geocell installation, follow these guidelines:

- Accurate Pre-Execution Design: All details, including slope, drainage, anchors, and infill materials, must be determined before starting the work.

- Panel and Material Coordination: Select panel width and dimensions according to the site width to minimize cutting.

- Use of Fast and Standard Connections: Apply proper clips, metal locks, or cable ties to speed up panel joining.

- Preparation of Tools and Equipment: Ensure all rollers, compactors, loaders, anchors, and cutting tools are ready before installation.

- Installer Training: The installation team must be familiar with panel unfolding, joining, filling, and compaction to minimize errors.

- Quality Control at Each Stage: After each layer, check cell expansion, infill uniformity, and compaction consistency.

- Protection Against Mechanical Damage: Avoid strong impacts to cell walls during filling or machinery movement.

- Final Inspection and Surface Cleaning: After completion, the final surface should be leveled and free from excess materials.

Summary: Quick Geocell Installation Guide

Fast and proper Geocell installation requires careful site preparation, the right panel and infill selection, and attention to key execution details. Using high-quality Geocell sheets from Shahriyar Baspar Aryan and consulting the company’s technical team will enhance installation speed and extend structural lifespan. For specialized technical guidance, contact the engineering department of Shahriyar Baspar Aryan or send your project details for consultation.

You can also purchase geomembrane welding machines by contacting Shahriyar Baspar Aryan’s technical experts.