The Difference Between HDPE and Other Geomembranes in Khanjani Polymer Industries

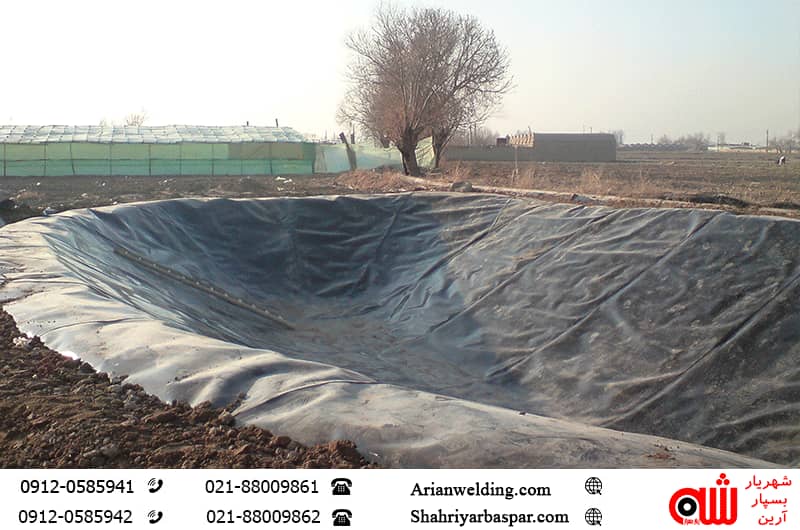

Geomembranes are among the most widely used geosynthetic materials in various industries, especially in the construction of reservoirs, ponds, canals, and landfills. Due to their chemical resistance, long service life, and acceptable flexibility, these products have become suitable alternatives to traditional materials such as concrete or stone. Among different types of geomembranes, HDPE (High-Density Polyethylene) is recognized as one of the most popular options. However, its differences compared to other geomembranes remain a key point of interest for experts and engineers. Khanjani Polymer Industries, with extensive experience in manufacturing and supplying geomembranes, has closely examined these differences.

1. Definition and Structure of HDPE

HDPE, or High-Density Polyethylene, is a thermoplastic polymer produced from ethylene monomers. Its molecular structure is highly compact, which results in excellent mechanical and chemical resistance. The main characteristics of HDPE include:

- High tensile strength

- Acceptable flexibility

- Chemical resistance against acids and alkalis

- Resistance to sunlight and UV radiation

These properties have made HDPE one of the primary choices for industrial and agricultural projects.

2. Types of Geomembranes

Geomembranes are classified into several categories based on their raw materials and mechanical properties:

- HDPE (High-Density Polyethylene)

- LLDPE (Linear Low-Density Polyethylene)

- PVC (Polyvinyl Chloride)

- EPDM (Ethylene Propylene Diene Monomer)

- PP (Polypropylene)

Each of these materials has unique characteristics and performs better under specific conditions.

3. Difference Between HDPE and LLDPE

LLDPE is also a type of polyethylene, but its density and molecular arrangement are lower than those of HDPE. The main differences include:

- Mechanical strength: HDPE has higher tensile strength and is more suitable for projects subjected to high pressure.

- Flexibility: LLDPE is more flexible than HDPE and is better suited for areas with complex curves.

- Cost: HDPE is usually slightly more economical than LLDPE due to simpler production processes.

Therefore, in projects such as large water reservoirs or industrial ponds, HDPE is typically the first choice, while LLDPE is more suitable for canal linings and smaller ponds with higher curvature.

4. Difference Between HDPE and PVC

PVC is another thermoplastic geomembrane that is popular in some projects due to its high flexibility and ease of installation. Key differences include:

- Chemical resistance: HDPE offers greater resistance to acids and alkalis, while PVC may deteriorate under harsh chemical conditions.

- Durability and service life: HDPE typically has a service life of up to 30 years, whereas PVC lasts about 15 to 20 years.

- Thermal resistance: HDPE can withstand temperatures of up to approximately 120°C, while PVC has lower heat tolerance.

For this reason, HDPE is a more reliable choice for water storage ponds, landfills, and industrial reservoirs and is fully compatible with Arian Weld geomembrane welding machines, which are exclusively manufactured and supplied by Shahriar Baspar Arian Company.

5. Difference Between HDPE and EPDM

EPDM is an elastomeric geomembrane with exceptional flexibility and strong performance at low temperatures. The differences include:

- Flexibility: EPDM is extremely flexible and suitable for areas with complex geometries.

- Chemical resistance: HDPE provides superior resistance to corrosive chemicals.

- Cost and installation: HDPE is easier to install and generally more cost-effective.

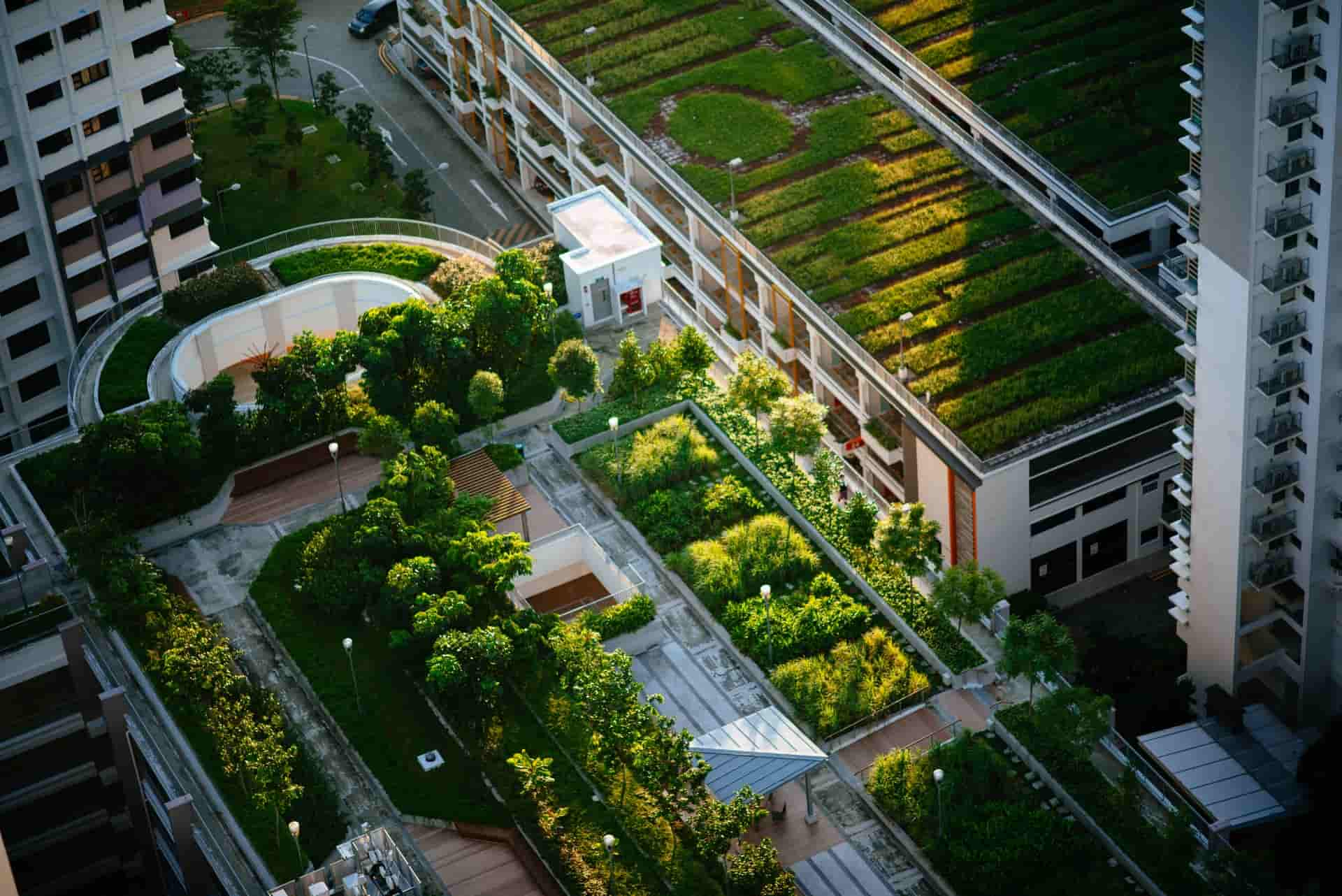

At Khanjani Polymer Industries, HDPE is usually recommended for large ponds and industrial projects exposed to high water pressure and chemicals, while EPDM is more commonly used for green roofs or small, irregularly shaped ponds.

6. Difference Between HDPE and Polypropylene (PP)

Polypropylene (PP) is another type of geomembrane used under specific conditions:

- Thermal resistance: PP performs better than HDPE at higher temperatures.

- Chemical resistance: HDPE is more resistant to most acids and alkalis.

- Flexibility: HDPE is more flexible than PP, making installation easier.

Therefore, for standard industrial projects, HDPE is generally the preferred option unless extremely high temperatures are involved.

7. Advantages of HDPE Over Other Geomembranes

Based on the experience of Khanjani Polymer Industries, HDPE offers the following advantages in large-scale and industrial projects:

- High durability and long service life, suitable for long-term projects

- Strong chemical resistance, ideal for reservoirs and landfills

- High mechanical strength, capable of withstanding significant stress and pressure

- Thermal weldability, allowing fast installation without chemical adhesives

- Cost-effectiveness relative to service life

- Resistance to sunlight and UV radiation

These features have made HDPE the top priority for many engineers and designers.

8. Applications of HDPE in Khanjani Polymer Industries

Khanjani Polymer Industries, with extensive experience in manufacturing and installing HDPE geomembranes, supplies these products for a wide range of projects, including:

- Agricultural and industrial ponds

- Irrigation canals and waterways

- Water and chemical storage reservoirs

- Landfills and waste disposal sites

- Green roofs and urban drainage systems

Summary: The Difference Between HDPE and Other Geomembranes

Due to its chemical resistance, long service life, weldability, and reasonable cost, HDPE is preferred over other geomembranes in many industrial and agricultural projects. While geomembranes such as LLDPE, PVC, EPDM, or PP may offer advantages under specific conditions, HDPE geomembrane remains an economical, reliable, and standard solution.

Khanjani Polymer Industries, with years of experience in the production, sale, and installation of HDPE geomembranes, can provide optimized, cost-effective, and long-term solutions for your projects.