Geomembrane or Bitumen Membrane? A Technical Comparison of the Best Roof Waterproofing Solutions

Choosing the right waterproofing material for roofs — especially in modern buildings that require both reliable sealing and long-term thermal performance — is a crucial technical and economic decision.

In this article, we present a professional and practical comparison between **geomembrane** and **bitumen membrane (isogam)** from technical, operational, economic, and environmental perspectives, helping you make an informed decision for residential, commercial, or industrial projects.

It should be noted that leading domestic manufacturers — including Khanjani Polymer Industries, recognized as one of the largest geosynthetics manufacturers in Iran — will be mentioned where relevant.

Definition and Material Composition

Bitumen Membrane (Isogam): Reinforced bituminous sheets made with polyester or fiberglass, often covered with protective layers such as foil, powder, or plastic film. Traditionally used for waterproofing roofs and floors, installed using gas torches and adhesive layers.

Geomembrane: A relatively thick polymeric sheet (usually made of PVC, HDPE, LLDPE, or PP) manufactured as continuous rolls. It’s primarily used for waterproofing and seepage control in reservoirs, tunnels, and flat roofs.

The sheets are joined using hot air or wedge welding, creating a seamless and highly watertight connection.

Waterproofing Performance

Bitumen Membrane: Performs well in the short to medium term if properly applied without defects. However, it is more vulnerable to punctures, local settlement, and root penetration (in green roofs).

Geomembrane: Due to welded seams and continuous structure, it offers far superior water impermeability and resistance to structural movement or chemical exposure.

Conclusion: For long-term and high-demand waterproofing applications, geomembrane provides a more reliable and durable solution.

Durability, Mechanical Strength, and Maintenance

Bitumen Membrane: Lifespan ranges from 8 to 15 years depending on material quality and installation. UV resistance is limited unless protected by a reflective layer. Repairs are simple but frequent due to cracking over time.

Geomembrane: When properly selected and installed, it can last over 20 years. It has higher tensile, tear, and chemical resistance. Maintenance is minimal and typically limited to inspection and welding-based patch repairs.

Conclusion: Geomembrane is technically superior in long-term durability.

Installation and Application

Bitumen Membrane: Fast and affordable installation requiring minimal equipment (gas torch, knife). However, open flame poses safety risks and execution errors are common in hard-to-reach areas.

Geomembrane: Requires professional installation, thermal welding machines, and skilled operators. Surface preparation and protection during installation are critical. It may cost more initially but ensures fewer future repairs.

Conclusion: Bitumen membrane is easier to install; geomembrane offers higher precision and reliability.

Thermal Performance

Neither material alone serves as an effective thermal insulator. They are typically combined with insulation layers such as XPS, mineral wool, or foam.

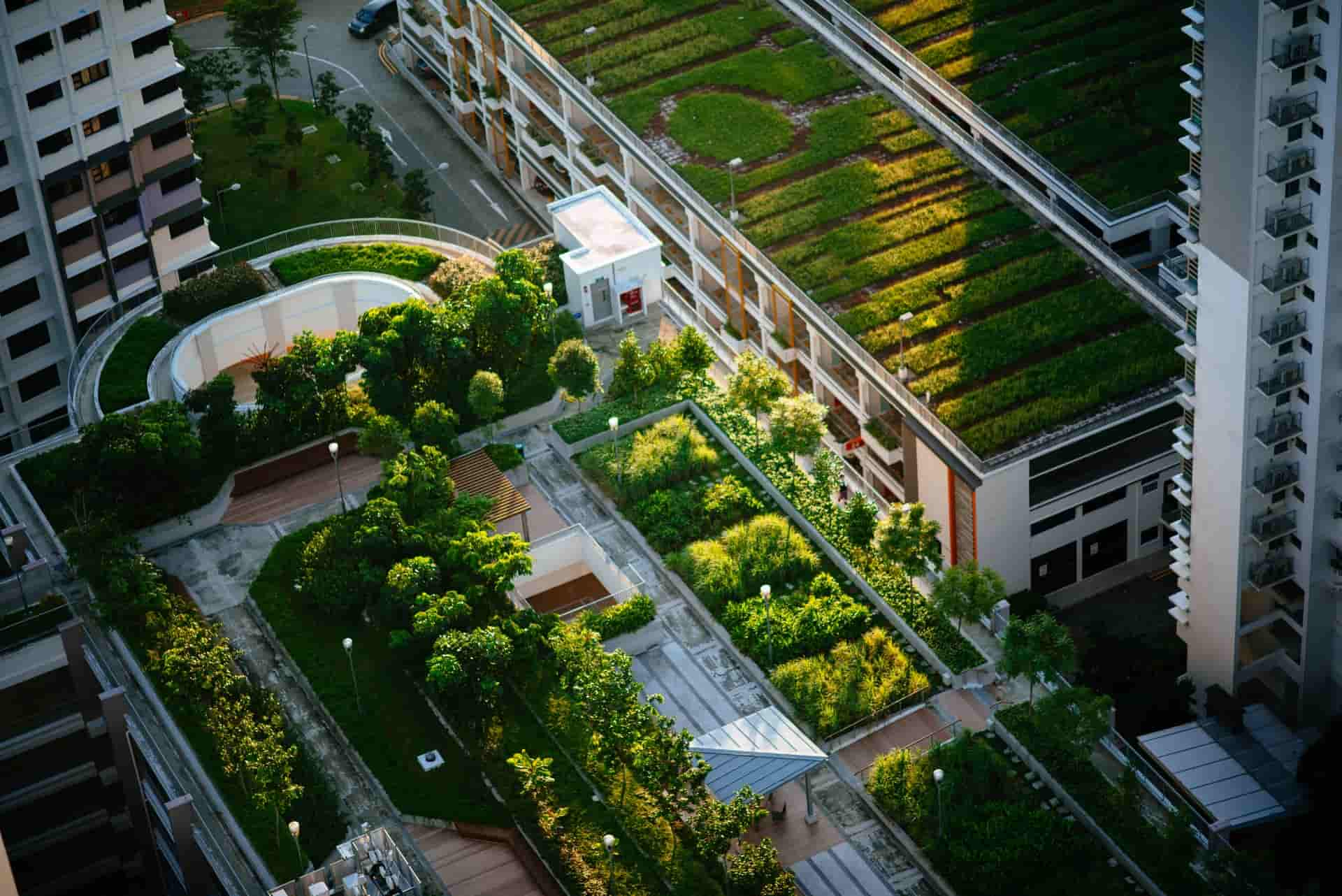

Geomembrane, due to higher density, performs better when integrated in green roof systems. Bitumen membranes tend to absorb more heat unless covered with reflective coating.

Life Cycle Cost (LCC)

Bitumen membranes are cheaper initially. However, when factoring repair, downtime, and leakage risks, geomembrane often becomes more cost-effective for long-term use — especially in commercial or high-value projects.

Environmental Impact

Bitumen membranes contain petroleum derivatives, posing challenges in production and disposal.

Geomembranes (especially HDPE types) are more recyclable and have longer service life, reducing material waste over time.

Recommended Applications

– Simple residential roofs with limited budgets → Bitumen membrane is acceptable if properly installed.

– Roof gardens, parking decks, and long-term waterproofing projects → Geomembrane is recommended.

– Industrial or commercial buildings with high leakage sensitivity → Geomembrane with professional supervision is the best option.

Key Technical and Installation Guidelines

- Select proper polymer type and thickness (HDPE or LLDPE for geomembranes).

- Ensure a clean, smooth substrate free from sharp objects.

- Protect sheets from direct heat and puncture using cushioning layers.

- Use trained technicians and perform post-installation leak tests.

- Implement periodic inspections and maintenance records.

Domestic Manufacturers and Material Sources in Iran

In Iran’s domestic market, several reputable geosynthetics manufacturers operate. Among them, Khanjani Polymer Industries stands out as one of the largest producers, offering high-quality geomembranes and related materials.

When purchasing, ensure the manufacturer provides quality certification, technical warranty, and after-sales support, as well as color-matched sheets for future repairs.

Summary: Professional Comparison Between Geomembrane and Bitumen Membrane

If you need a quick, low-cost waterproofing solution for non-critical roofs, bitumen membranes are suitable.

However, if long-term durability, low maintenance, and watertight performance are priorities — especially for high-risk or heavy-load roofs — geomembranes are the superior choice.

Before final selection, consider roof type, budget, installation expertise, and maintenance requirements, and request technical consultation and samples from a geomembrane manufacturer such as Khanjani Polymer Industries.

📞 For consultation and purchase:

Shahriyar Baspar Arian Company

☎️ Phone: +982188009862

🌐 Website: www.shahriyarbaspar.com

✉️ Email: info@khanjanipolymer.com