Guide to Choosing Polymeric Sheets (Geomembranes) for Agricultural Ponds

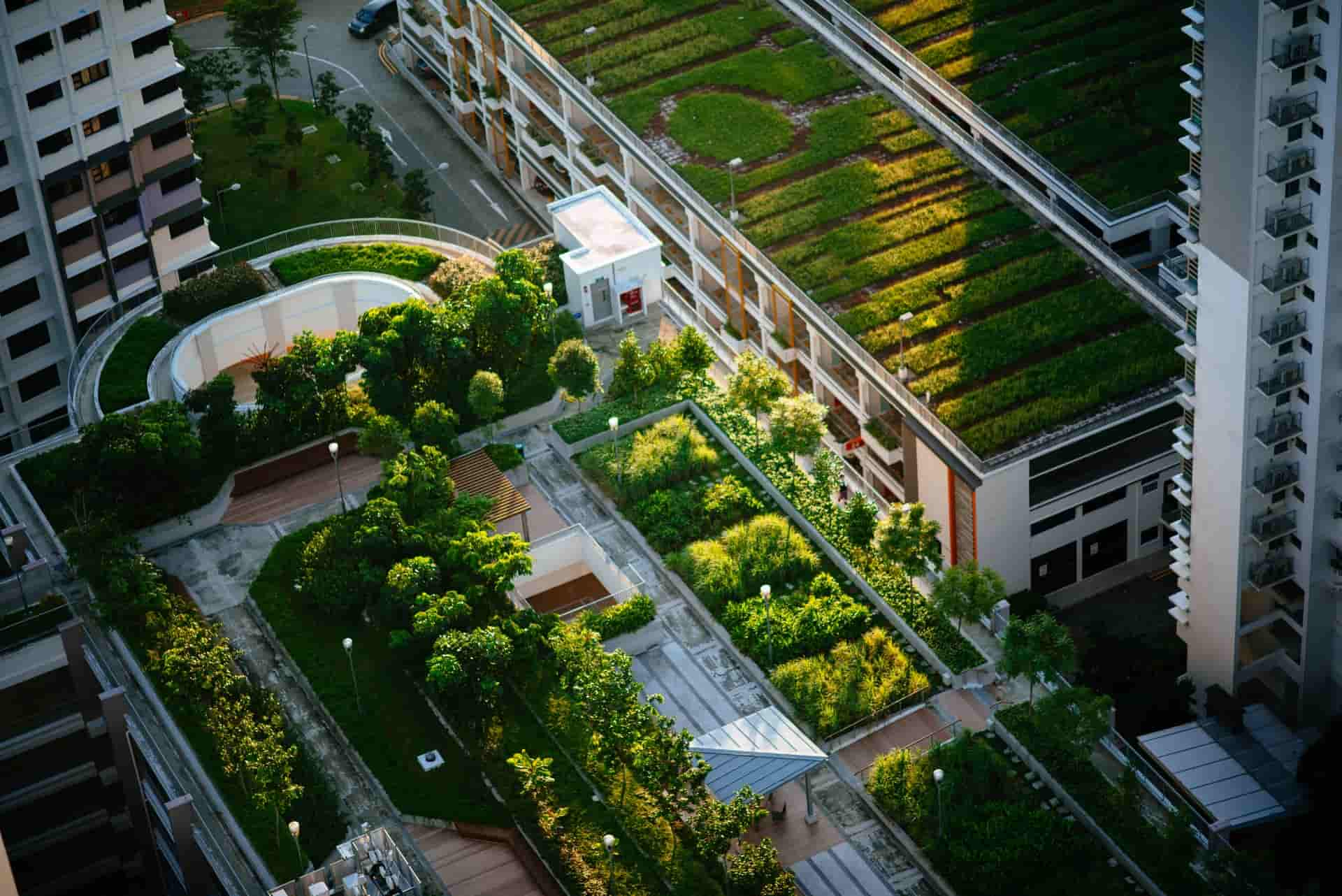

The water scarcity crisis and the need for efficient water resource management in Iran’s agricultural sector have highlighted the importance of effective water storage. Agricultural water storage ponds are a vital solution to ensure sustainable crop production. Traditionally, methods such as concrete and earthen ponds faced major challenges, including severe water loss from leaks, cracking, algae growth, and high maintenance costs.

Expertise and Reliability in Water Storage with Khanjani Polymer Industries: The Largest Producer and Supplier of Geomembrane Welding Machines in Iran and the Middle East

Today, polymeric sheets, also known as geomembranes, have revolutionized pond lining, offering a reliable and cost-effective alternative to traditional methods. Choosing the right geomembrane is a key decision that directly impacts the project’s lifespan, performance, and overall cost. Khanjani Polymer Industries, as the largest producer and supplier of geomembrane welding machines in Iran and the Middle East and a leader in providing high-quality, standardized polymeric sheets, helps you make a scientific and economical choice.

Section 1: Why Geomembranes Are the Best Option for Agricultural Ponds (Compared to Traditional Methods)

Geomembranes are made from highly impermeable polymers and offer the following advantages over traditional materials (concrete and stone):

- Service Life: 20 to 50 years with reliable warranties.

- Leak-Proof and Watertight: 100% impermeability (complete seal), unlike traditional materials prone to leaks and cracks.

- Installation Cost: Significantly lower (about 1/5 of traditional methods) compared to high material and labor costs.

- Installation Speed and Ease: Very fast (few days) without drying time, versus weeks or months for traditional methods.

- Environmental Resistance: High resistance to UV, cold, cracking from temperature changes, freezing, and earthquakes.

- Chemical Neutrality: Resistant to chemicals and acids, suitable for drinking water and aquaculture, unlike traditional materials.

Geomembranes not only retain water but also help farmers optimize their investment by reducing initial and maintenance costs.

Section 2: Types of Polymeric Sheets (Geomembranes) for Agricultural Ponds

Polymeric sheets for agricultural ponds mainly come in two types, each with unique properties:

1. High-Density Polyethylene (HDPE) Geomembrane – The Most Common and Reliable Choice

HDPE geomembranes are the most widely used in agricultural water storage projects.

Advantages:

- High chemical resistance: Resistant to most acids, chemicals, and fertilizers.

- UV resistance: Long-lasting under direct sunlight.

- High tensile strength and rigidity: Ideal for large, deep ponds with hard soil beds.

- Safe for drinking water and aquaculture: Chemically inert and non-reactive.

- Limitation: Less flexible than LLDPE, requiring careful preparation and installation of the pond bed.

2. Linear Low-Density Polyethylene (LLDPE) Geomembrane – Extremely Flexible

LLDPE offers similar chemical resistance to HDPE but with higher flexibility.

Advantages:

- Excellent flexibility: Suitable for irregular pond beds or soils prone to settling.

- Puncture and tear resistance: Due to higher elasticity.

- Limitation: Lower tensile strength compared to HDPE, which may require increased thickness for very large or deep ponds.

Khanjani Polymer Industries recommends HDPE with suitable thickness for most agricultural ponds, especially in sunny regions with standard soil beds, as it provides the best balance between performance, lifespan, and cost.

Section 3: Key Factors in Choosing Sheet Thickness and Width

Selecting the right thickness and width is critical for project stability and cost-effectiveness.

1. Sheet Thickness (mm)

Thickness usually ranges from 0.5 to 3.0 mm, depending on:

- Pond depth and volume: Deeper, larger ponds require thicker sheets (usually 1.5–2.0 mm).

- Soil quality: Rocky or root-filled beds may require thicker sheets or a protective geotextile layer.

- Usage type: Fish ponds often need thicker sheets due to higher risk of damage.

2. Sheet Width (m)

Geomembranes are produced in various widths (e.g., 2.2, 5.0, 7.0, 8.0 m). Width choice affects quality and cost:

- Welding machine impact: Wider sheets reduce the number of seams and speed up installation. Khanjani Polymer Industries provides the largest and most advanced welding machines for wide-sheet installation.

- Uniform thickness: Some manufacturers thin the central portion to save costs. Khanjani emphasizes consistent thickness across the sheet for maximum water pressure resistance.

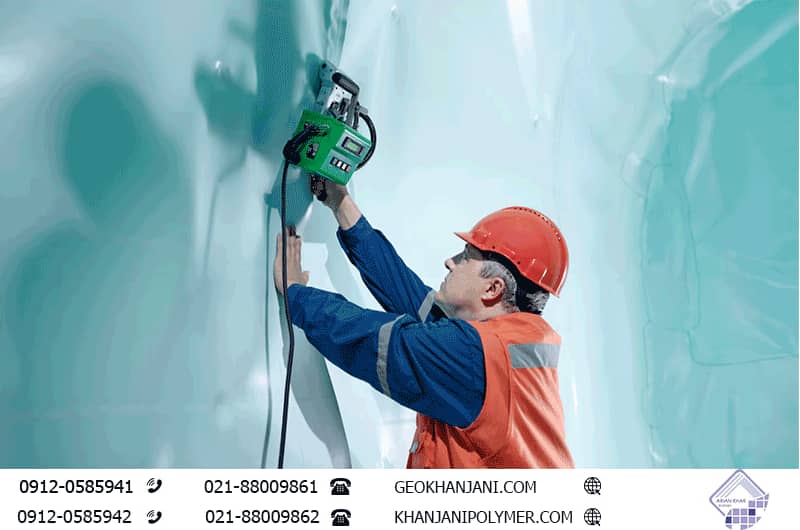

Section 4: Importance of Proper Welding and Installation (Khanjani’s Role)

Even the best geomembrane fails if not properly welded and installed. Welding is the core of watertight performance.

1. Geomembrane Welding Machine (Wedge Welder)

Sheets are welded using specialized thermal methods (fusion or extrusion) with advanced machines. Khanjani Polymer Industries ensures:

- Use of standard equipment: Thermal welding machines can create double seams and allow leak testing, maximizing watertightness.

- Installation expertise: Professional installers use approved machines and have the technical knowledge for correct application on any soil bed.

2. Installation and Bed Preparation Steps

Successful ponds require:

- Excavation and leveling: Remove rocks, roots, and sharp objects.

- Proper slope: Walls angled according to soil type (usually 30° to 6°) to prevent collapse.

- Geotextile layer (highly recommended): Protects the geomembrane from mechanical damage in soft or rough beds.

- Sheet spreading and welding: Spread sheets with minimal tension and weld seams precisely.

- Leak testing: Perform air or vacuum pressure tests on seams for full watertightness.

Conclusion: A Choice for the Future

Choosing polymeric sheets for agricultural ponds is more than a simple purchase; it is a long-term investment in water resource sustainability and operational cost reduction. With unmatched durability, long lifespan, and fast installation, geomembranes are the ideal solution for water management in agriculture.

Khanjani Polymer Industries provides high-quality, uniform-thickness geomembrane sheets and the largest fleet of standard welding machines, serving not only as a supplier but as a reliable partner in water storage projects.

For informed decisions and guaranteed quality at every stage, benefit from the expert guidance and standardized geomembrane sheets from Khanjani Polymer Industries.