Home » Heap Leach Ponds

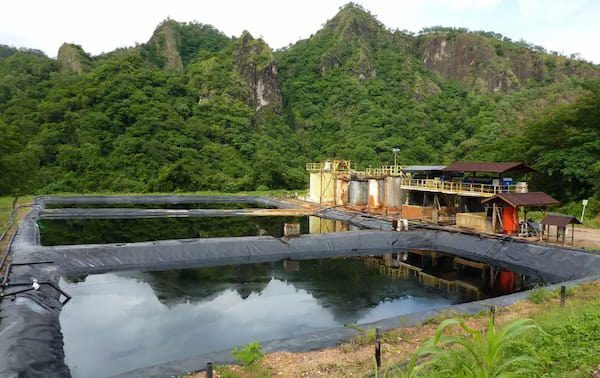

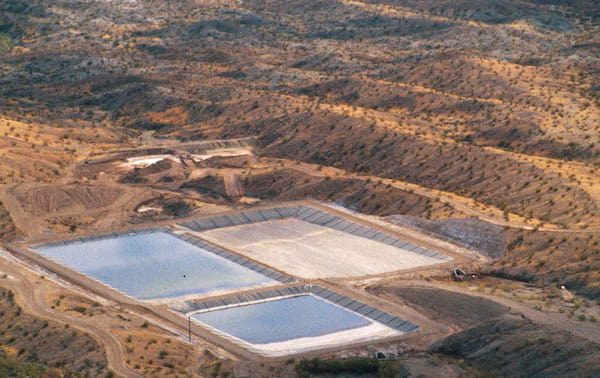

“The use of heap leach ponds with geomembrane lining in the extraction of precious metals (such as gold, copper, and silver) at Khanjani Polymer Industries represents a combination of advanced technology and environmental efficiency. In this process, ore is placed on a stable base and irrigated with chemical solutions (such as cyanide or sulfuric acid). The resulting leachate, containing extracted metal ions, is collected by the geomembrane system, preventing infiltration into soil and groundwater aquifers.

Common geomembranes include HDPE and LLDPE, which provide high chemical resistance, excellent tensile strength, and long service life. These liners deliver reliable performance under harsh environmental conditions, UV exposure, temperature fluctuations, and heavy loads.

Typical systems include:

Overall, the application of geomembranes in heap leach ponds at Khanjani Polymer Industries results in:

Heap leach ponds are one of the key methods in the mining industry for extracting precious metals such as gold, silver, and copper. The principle of these ponds is based on the leaching process, where crushed ore is heaped on a base lined with durable HDPE or LLDPE geomembranes and then irrigated with chemical solutions (such as sodium cyanide or sulfuric acid).

This process consists of several main stages:

To receive free expert advice, information about prices, and to place an order, you can contact our experts at Khanjani Polymer Industries.

ارتباط با مشاورین ما

👋نیاز به راهنمایی دارید؟

کارشناسان صنایع پلیمری خانجانی آماده پاسخگویی به سوالات شما هستند.